How to configure the right Module Level Rapid Shutdown for your power station--24V DC cable version

Date: 2022-06-10At present, countries around the world, such as the United States, Canada, Thailand and other countries have successively introduced rapid shutdown regulations to solve the safety of photovoltaic power plants.

First of all, let's understand what is the causes of the safety problem of photovoltaic power plants?

Photovoltaic power plants have great safety hidden trouble

In photovoltaic power generation systems, as long as there is light illuminating the photovoltaic module, the DC side will generate DC voltage, and these DC voltages may be as high as 600-1500V. Although inverters in current photovoltaic systems can shut down the system under certain circumstances. However, the inverter can only turn off the voltage from itself to the grid side, and there will be high-voltage direct current between PV modules and cables between the module array and the inverter that cannot be turned off, posing a major threat to personal safety.

When the photovoltaic power station has been operating for 20 years. Over time, equipment aging, component hot spots, string mismatches, cable damage, connector failures, and DC arcing may cause fire accidents.

Once a fire occurs in the photovoltaic system, because there is still a high pressure of 600-1500V on the DC side, it will be much more difficult for firefighters to rescue the fire equipped with the photovoltaic system.

At present, brands such as PROJOY have successively launched Rapid shutdown products. By installing a module-level shutdown device, it is ensured that each component is in an open circuit state. In an emergency, it can be shut down remotely or manually, and the voltage is reduced to less than 80V within 30 seconds, achieving "component-level shutdown".

For different markets, according to NEC 2017&2020(690.12) regulations, PROJOY has launched two solutions: DC 24V Rapid Shutdown & PLC Rapid Shutdown.

What is the DC 24V type Rapid Shutdown?

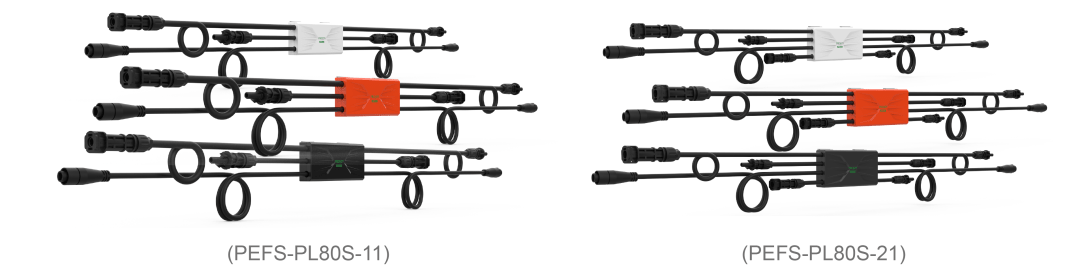

First, the popular explanation is to actively provide power for fast shutdown devices. At present, PROJOY has launched two versions of fast shutdown in response to market demand: PEFS-PL80S-11 and PEFS-PL80S-21. Users can choose suitable rapid shutdown products for their power stations according to actual needs.

<PROJOY DC 24V Rapid Shutdown>

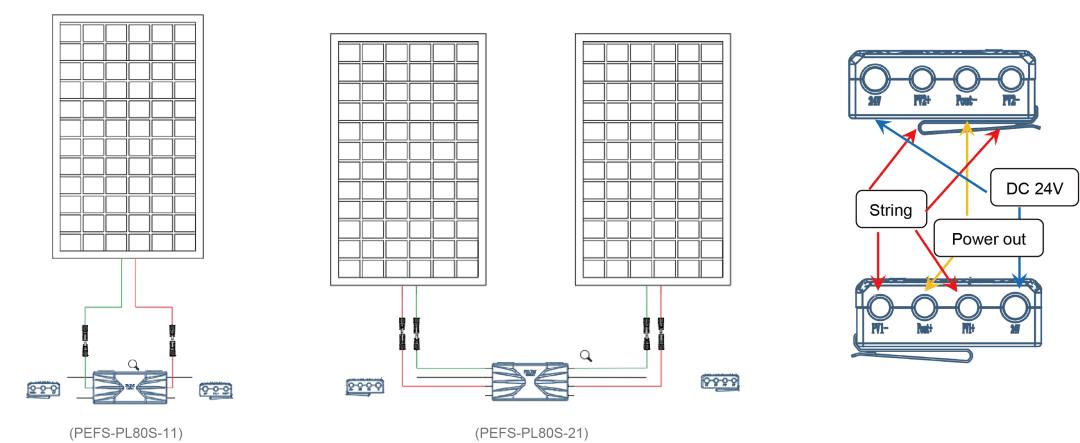

Normally, PEFS-PL80S-11 is connected in series with one photovoltaic panel, and PEFS-PL80S-21 is connected in series with two photovoltaic panels.

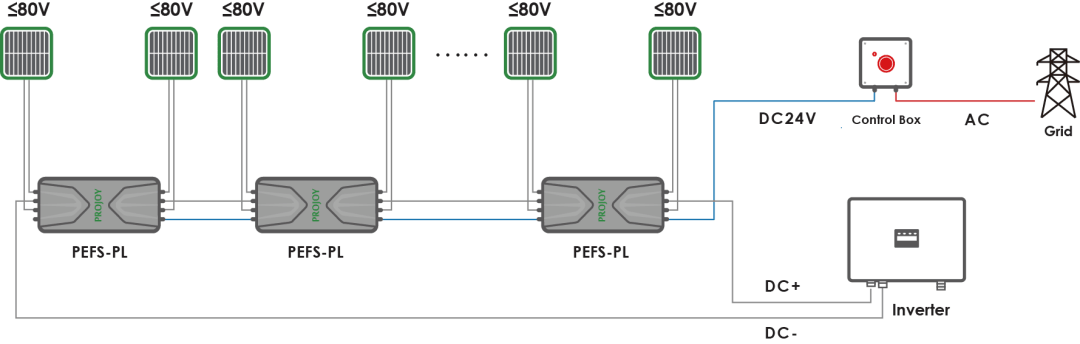

<PROJOY DC 24V Rapid Shutdown Typical Wiring Example>

PROJOY PEFS-24V-CN series control box: there are two kinds of built-in power module and external power module, usually used together with rapid shutdown.

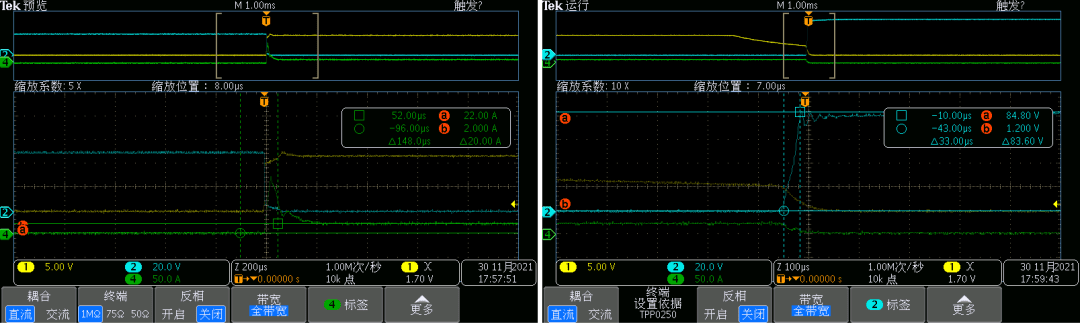

When encountering a fire or an emergency, we can transmit the signal to the shutdown device by disconnecting the AC mains or pressing the rapid shutdown emergency button to quickly extinguish the arc within 10ms, and remotely shut down the power station as soon as possible. If it needs to be reset again after it is turned off, it can be powered on directly, and the signal can be restored within 1ms.

<PROJOY DC 24V Rapid Shutdown power station measured shutdown time>

How to configure products for your power station?

Rapid shutdown one fits one wiring scheme

In general, in order to meet regulatory compliance, or the combined rating of the two PV panels has exceeded the rating of the PEFS-PL80S-21, it is recommended to use a one fits one wiring method. Directly connect the positive (+) output of the PV panel to the positive (+) input of PROJOY PEFS-PL80S-11, and connect the negative (-) output of the PV panel to the negative (-) input of the PEFS-PL80S-11.

When the open circuit voltage of the photovoltaic panel is lower than 80V, the PEFS-PL80S-11 can be selected in series with a photovoltaic panel.

<PEFS-PL80S-11 One fits one wiring>

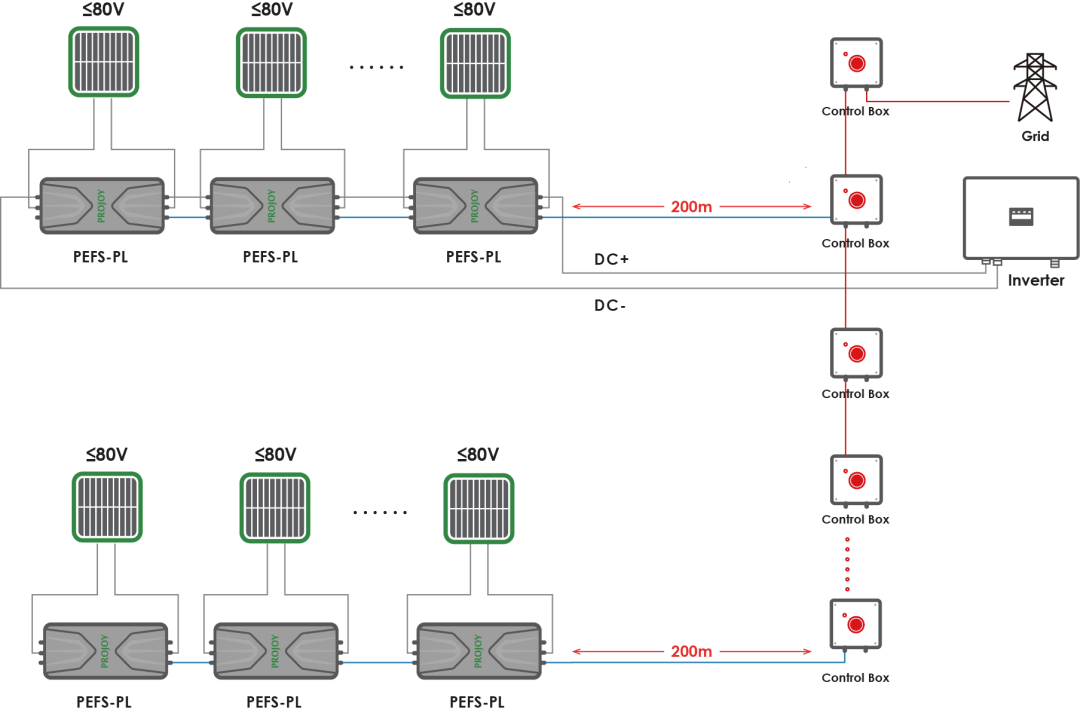

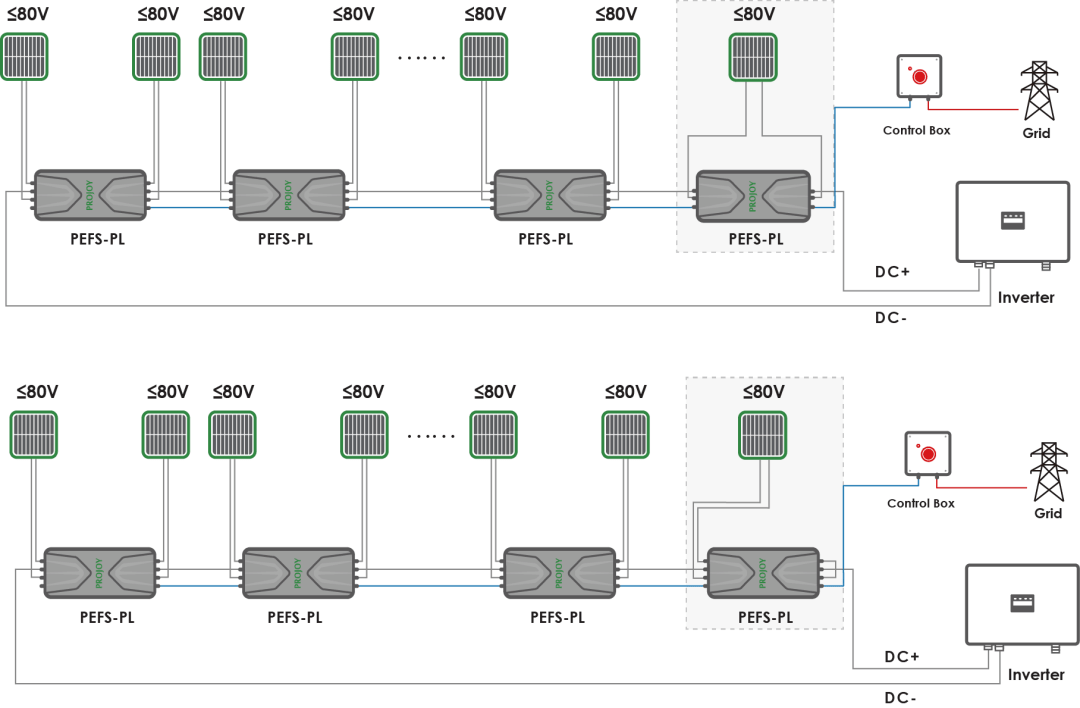

When the number of photovoltaic panels in our power station is more than 60, multiple control boxes can be used to connect in parallel, and up to 10 control boxes can be connected in parallel.

<PEFS-PL80S-11 Multiple control box wiring methods>

Rapid shutdown one fits two wiring scheme

Usually, from an economical point of view, the one fits two wiring method is generally chosen, which is cheaper. In this case, if the number of photovoltaic panels is an even number, all of them need use the one fits two.

<PEFS-PL80S-11 One fits two wiring method 1>

When the number of photovoltaic panels is an odd number, the last one uses a one fits one rapid shutdown, or a one fits two rapid shutdown to connect only one channel.

<PEFS-PL80S-11 One fits two wiring method 2>

Similarly, when the number of photovoltaic panels in our power station exceeds 120, multiple control boxes can be connected in parallel, and a maximum of 10 control boxes can be connected in parallel.

The importance of rapid shutdown for photovoltaic power plants is self-evident, and the laws and regulations of various countries will continue to be gradually improved. How to configure products will also be an important part. Economy and safety are equally important!