Coming icebreaking, PROJOY new arrivals may open a new page to solutions to PID

Date: 2015-11-19So far as the photovoltaic industrydevelops, installed capacity of power plants keeps rising, but in the past few decades, the efficiency of more and more the PV power plants drops after three or four years operation, resulting in significant losses. One of the reasons, apart from the quality issues of different modules and the installation environment, is the PID effect, which may cause serious degradation of modules, sometimes even by more than 50%, thus affecting generating capacity of the entire system and the total output power, lowering investment yields of photovoltaic power plants.

Many users in Japan specifically requested that the anti-PID be written in the contract with a random sampling and European buyers have also made the same request.

PID Definition

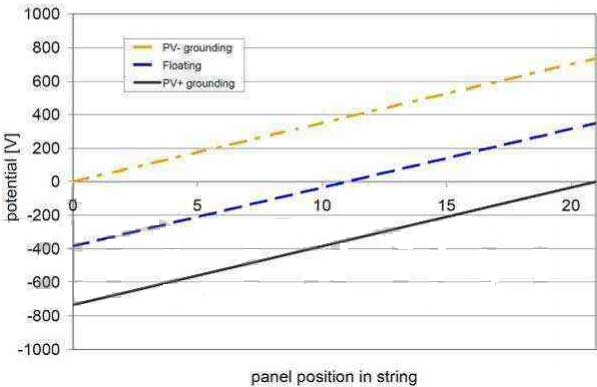

Potential Induced Degradation, as the designation implies, occurs when the module’s voltage potential and leakage current derivation mobility within the module between the semiconductor material and other elements of the module (e.g. glass, mount and frame), thus causing the module’s power output capacity to degrade.

National Renewable Energy Laboratory previously confirmed the risk regardless of what technology the P-type crystalline silicon solar panel is based, modules in the negative bias has the PID. In 2005, Chinese PV panel manufacturers for the first time reported the phenomenon and after that photovoltaic power plants in Europe and America also found a substantial decline in output power. Such phenomenon has become a big problem. PID effect has become, in recent years, one of the painful complaints from international buyers onthe quality of panels made in China.

Traditional solutions to PID effects

Currently, inverter manufacturers, module manufacturers are looking for the best solution to PID effect. What is it?

1.PID effect approaches from module manufacturers:

At present, module manufacturers, research institutions, major photovoltaic laboratory and testing facility have not come to an agreed conclusion on the real causes of PID, due to the diversity and complexity of factors. Therefore, when dealing with PID effect, recognized research directions for module manufacturers are:

Blocking the leakage flow circuit from forming by employing non-Na, Ca glass to improve the resistivity of the glass and adopting non-ethylene - vinyl acetate copolymer asthe packaging material.

It can be found in dealing with PID effect international module manufacturers mainly use a recombination of EVA, glass, backing material, packaging material. In this process modulesare made of suitable and high quality solar cells and packaging material to effectively reduce the occurrence of the phenomenon of PID. However, this measure does not fundamentally solve the PID issue, and lead to increased initial cost of the entire power plant construction.

2.PID effect approaches Inverter manufacturers:

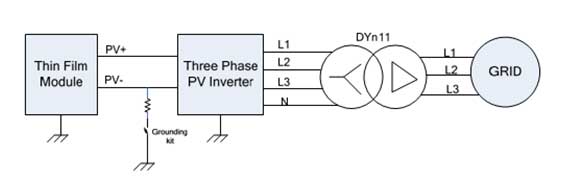

Throughstudies, the majority of PID phenomenon is reversible.When modules suffering PID are exposed to a positive bias voltage for some time, PID effect disappears. Inverter manufacturers usually adopt the negative grounding or virtual negative grounding approach of an isolation transformer, hence cancellingthe negative bias of PV modules.

An obvious disadvantage of this scheme is that when the system uses transformerless inverters plus isolation transformer scheme several major potential dangers will arise:

(1) PV- grounding and overvoltage between PV and +PE;

(2) electrical shocking of personnelby touching PV +;

(3) PV- grounding, and should the PV + or string cables between panels has the ground fault, a fault current is generated through the ground or arcing occurs,likely causing a fire;

(4) the cost is relatively high and the isolation transformer takes relatively large space.

Therefore, this scheme is unsuitable for string type power station applications, but more suitable for smaller centralized systems or a large-capacity system application program with isolation transformers.

Projoy-PID proposes new solutions

Projoy has launched a new product -Anti PID device, which adopts the principle of reversible PID, where during the night a positive bias voltage is imposed onmodules and hencethe PID effect is neutralised.

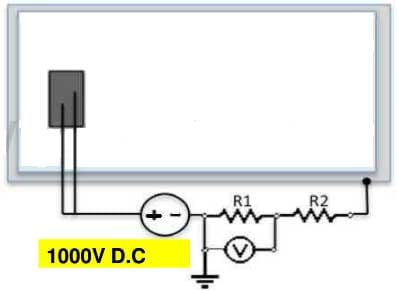

Working principle:

Projoy-PID and the inverter are connected in parallel to DC input and a high voltage is applied between the negative ofphotovoltaic modules and the ground (PE) while intelligent adjustment can be performed on the DC input voltage. At night, it can discharge the electric charges accumulated during the daytime because of the negative bias between the negative and the ground in PV modules and thereby repairsthe photovoltaic modules where PID has occurred. This device is featured withground-PV modules insulation resistance inspection (including PV modules and inverters, system impedance must be greater than 200kΩ) and grid voltage detection.

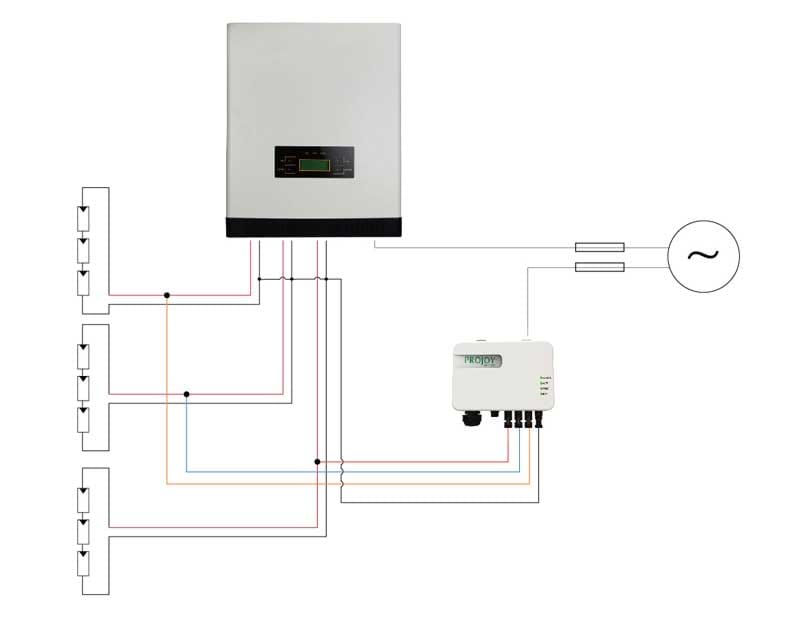

Projoy-PID supports the inverter of 1-, 2- or 3- MPPT’s, and each MPPT may be connected in parallel by multiple strings.

Connection diagram:

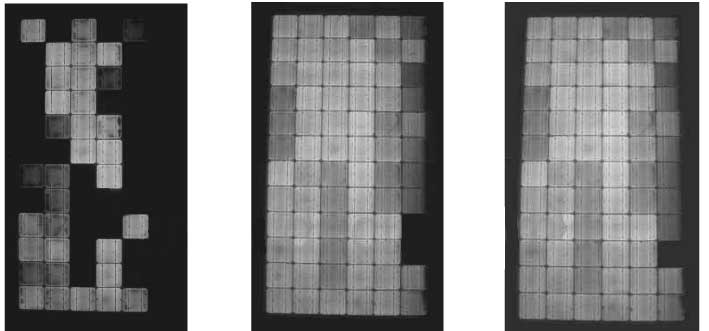

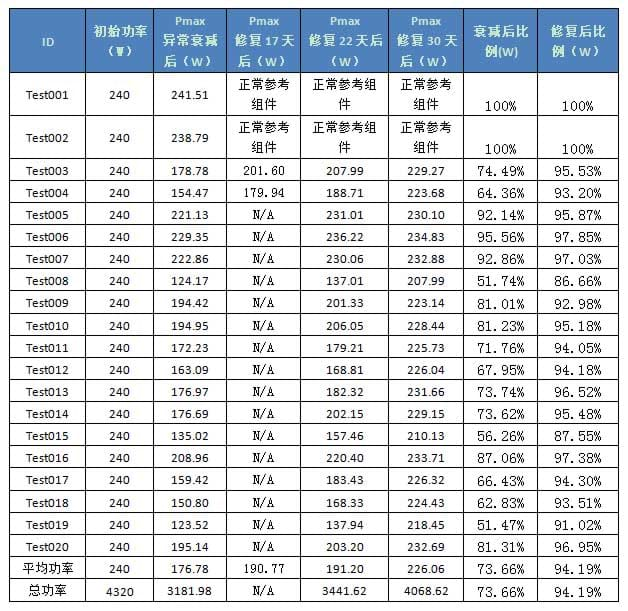

Below is the results of repairing by Projoy-PID: of the solar panels running over three years

Advantages to this PID Solution are:

1) low cost

2) that it does not affect the original structure of the photovoltaic system, without additional risks

3) convenience to install

4) good performance

Based on the user’s point of view, the Projoy R&D team constantly develops new product ranges and provides customers with appropriate solutions. Through continuous efforts, it has become a global professional invertersupplier and PV power plant solution provider.

PROJOY ELECTRIC SRL is a professional electrical manufacturer. We are committed to providing high and low voltage DC switching, intelligent components and sensors for the energy conversion equipment and energy intelligent management. The company is headquartered in Milan, Italy, with the establishment of subsidiaries in several countries Britain, China, to meet the demand of international marketing.