How to select a suitable DC MCB?

Date: 2020-03-15What is Miniature Circuit Breaker?

A miniature circuit breaker (MCB) is a switch device which closes, carries and breaks the circuit. It could open the circuit when the circuit current beyond a limited value. Usually, an MCB could be replaced by an isolator with a fuse.

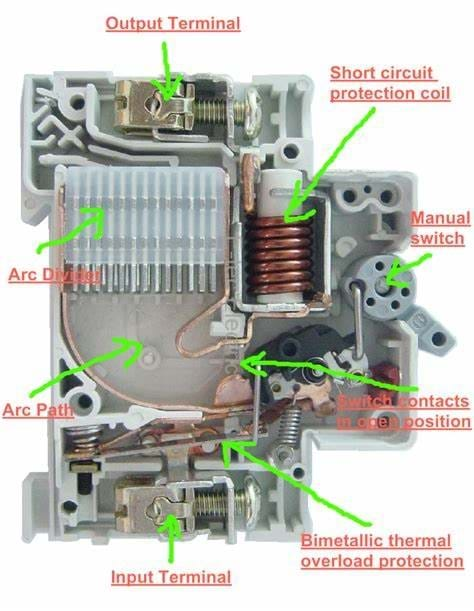

<Figure 1 MCB internal structure>

MCB working principle

An MCB is a switch device that carries rated current or switches fault current. These devices can automatically open the circuit (which has been connected to it) when the circuit current goes beyond a set value or limit, and be manually switched ON or OFF just like normal switches whenever necessary.

Automatic operation / trip MCB can be obtained in two ways: magnetic trip and thermal trip.

During an overload, the current flowing through the bimetal will cause the temperature of the bimetal to rise. The heat accompanying the temperature rise in the bimetal then causes bending in the bimetal due to the expansion of the metal. The deflection releases the trip latch and separates the contacts.

<Figure 2 Projoy Electric AC MCB>

In short circuit or heavy overload situations, magnetic tripping is activated more. Under normal working conditions, the slug is held in place by the light spring. This is because the magnetic field created by the coil is not strong enough to attract the latch. When there is a problem in the circuit, and current flows through it, the magnetic field created by the coil is strong enough to pull the spring holding the slug in position thereby moving the slug and activating the tripping mechanism.

Most MCBs combines both thermal and magnetic tripping mechanisms. In both operations, an arc is formed when the contacts start separating. Then through an arc path, the arc is forced into arc divider. The arc divider plates are also referred to as arc chutes. In which an arc is formed into a series of arcs and at the time, energy is extracted. Therefore, the arrangement interrupts arcs.

Types of MCB

Miniature circuit breakers are mainly divided into AC MCB and DC MCB. There is no big difference on parameter view. The difference between AC and DC MCB is only that AC MCB marks the terminals as LOAD and LINE terminals, and the terminals of DC MCB will have a positive (+) or negative (-). In fact, compared with AC MCB, DC MCB is more difficult to switch off DC current. The AC MCB works with the help of the zero crossing of the AC current, while the DC MCB works only depends on the mechanical construction. Compared with AC circuit, DC circuit need the MCB opened faster, which even increase the difficulty of MCB. The two types of MCBs are respectively divided into two types: Polarity/Polarized and Non-polarity/Non-polarized.

Polarity AC MCB

If the manufacturer indicates the “Input/Line” marks on the MCB, the power supply must be placed on the "Input/Line" terminal and the load must be placed on the "Load/Output" terminal for the MCB to operate properly. If connected incorrectly, the MCB will most likely not provide the expected protection to the circuit when needed.

Non-polarity AC MCB

For non-polarity AC MCB, manufacture don’t indicate any mark on the products. Users could connect the power to either terminal and connect the load to the other.

Polarity DC MCB

<Figure 3 DC MCB>

Polarity DC MCBs are marked with "+" and "-". If the polarity DC MCB is connected incorrectly, problems may occur, and under overload or short circuit conditions, the MCB will be not able to cut off the current and extinguish the arc, which may cause the circuit breaker to burn out.

The polarity DC MCB uses a small magnet to pull the arc from the contact and enter the arc extinguishing chamber. If the current flowing through the unit is in the opposite direction, the magnet will guide the arc out of the arc extinguishing chamber and into the MCB mechanism, damaging the equipment.

Non-polarity DC MCB

Non-polarity DC MCB are not marked with "+" and "-" signs. These MCBs can be safely used as load isolators and protect the circuit in the event of a fault current, regardless of the current direction in the circuit. Especially for circuits with energy storage batteries, the current often needs to be reversed as required, and non-polarity DC MCB can effectively provide protection.

Main parameters of MCB

There are three main parameters except rated voltage and rated current, rated overload current, ultimate short-circuit breaking capacity, trip characteristic curve.

Rated overload current

If there are too many loads on the circuit, the actual current will be over the current which the circuit could withstand. In this case, the MCB should switch off the load to protect the cables and other devices.

Ultimate short-circuit breaking capacity

If a fault occurs somewhere in the circuit, the circuit will be short-circuited, and the current at this time will reach hundreds to thousands of times as usual. MCB needs to disconnect the power in a very short time to avoid accidents such as damage to the appliance or fire. Therefore, the MCB is required to still have the ability to interrupt the fault current under the rated short-circuit current, and to ensure that the action is completed within the specified time limit.

Trip characteristic curve

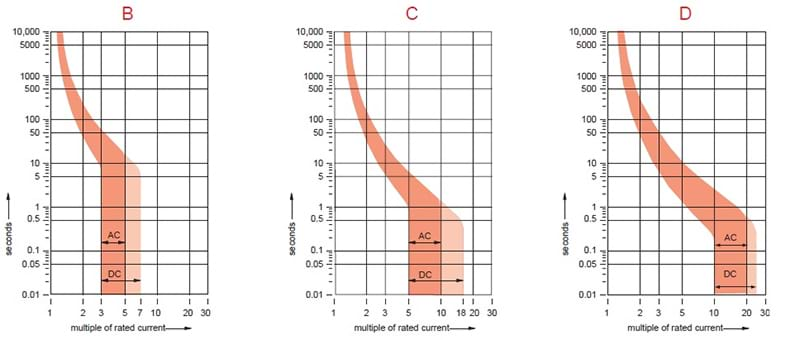

<Figure 4 MCB trip characteristic curve>

B type MCB

This type of MCB is designed to trip at 3 to 5 times of rated current. These MCBs are usually used for small inductive or resistive loads where switching surges are very small. So, they are suitable for residential and light commercial usage.

C type MCB

This type of MCB is designed to trip at 5 to 10 times of rated current. These MCBs are usually used for high inductive loads where switching surges are high such as in fluorescent lighting and small motors. So, they are suitable for industrial and highly inductive commercial installations.

D type MCB

This type of MCB is designed to trip at 10 to 20 times of rated current. They are usually used for extremely high inductive loads where high surge currents are very frequent. So, they are suitable for X-ray machines, UPS systems, large winding motors, and industrial welding equipment.

Other types, such as A type, K type, Z type is not introduced in this article.