PROJOY DC isolator won the world's first IEC latest standard (IEC60947-3(ed.3.2):2015) TUV cert

Date: 2017-06-25For a long time, high cost of photovoltaic power generation is always one of the obstacles to the rapid development of photovoltaic industry. At present, the PV industry supporting components are designed and manufactured base on the DC terminal 1000V voltage requirements. From the beginning of 2015, 1500V photovoltaic system has gradually become the market mainstream. In order to adapt to the new trend, from 2015 photovoltaic DC isolator manufacturer PROJOY Electric co ltd is committed to the rated voltage 1500V new DC switch design and development.

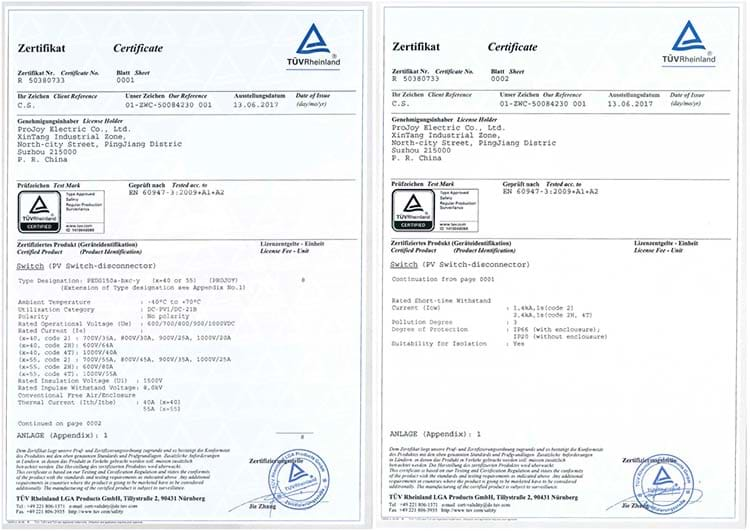

Recently, Projoy Electric announced that its 1500V series DC isolator 40A/55A has been successfully awarded the German TüV Rheinland Group issued TUV certification.

PROJOY DC isolator won the world's first IEC latest standard (IEC60947-3(ed.3.2):2015) TUV certification

The certification means the PEDS series 40A/55A DC isolator has become the world’s first isolator passed IEC60947-3 (ed.3.2): 2015 new standard, and also the only Chinese DC isolator has the 40A/ 55A TUV certification.

IEC new standards, new test

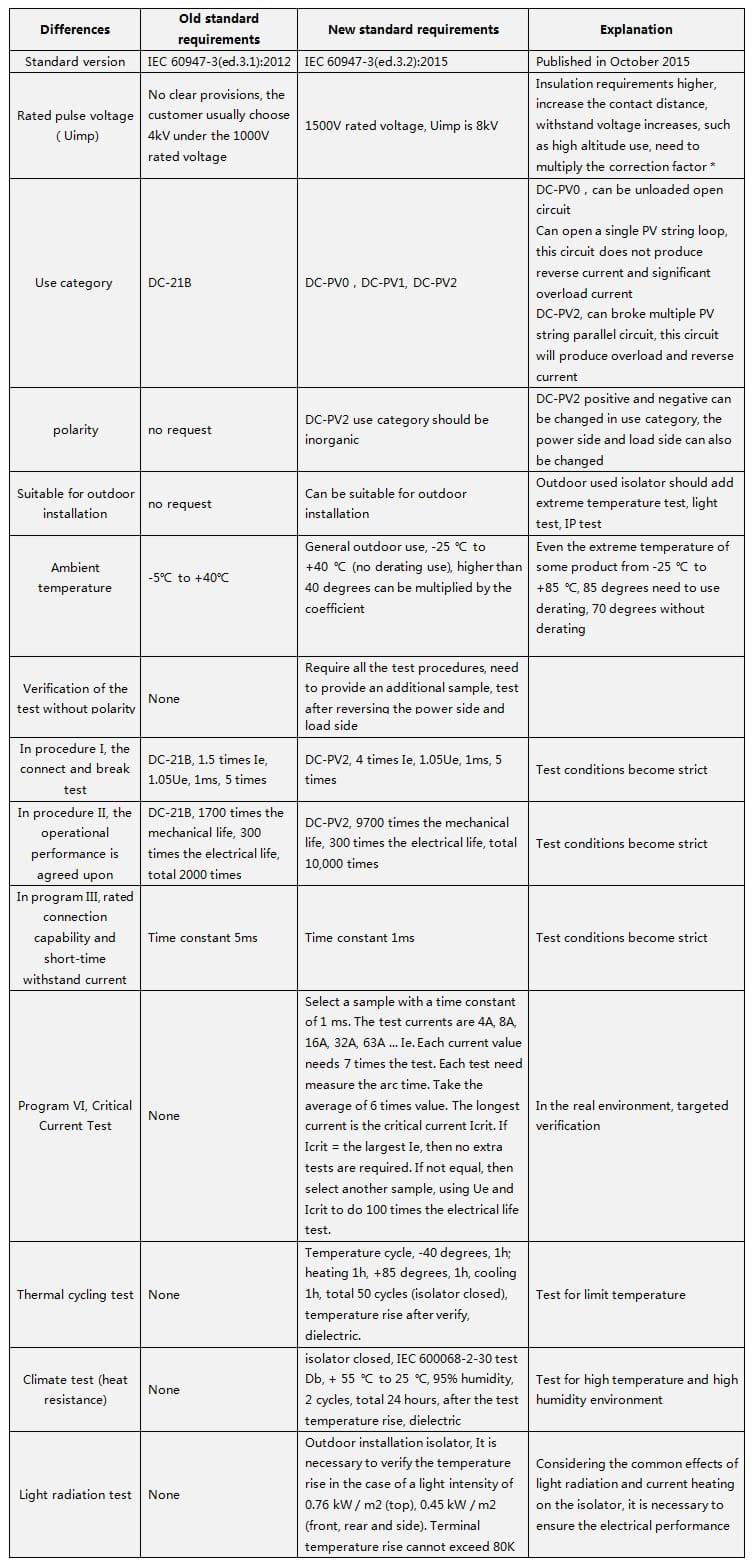

For the photovoltaic electrical products, IEC International Electro technical Commission in 2016 updated the new standard IEC60947-3 (ed.3.2): 2015. In contrast to the old standard IEC60947-3 (ed.3.1): 2012, the new standard also poses a higher demand for product performance.

Through the above table we can found, IEC60947-3 (ed.3.2): 2015 new standard increases the critical current test and thermal cycling and moisture resistance test, while the higher pulse voltage is to enable the switch to be suitable for highland areas. Not only that, compared to the older standard, the IEC new standard test requires a greater time constant and a smaller arcing time, which have put forward higher requirements of PV DC switch insulation performance, on-off capacity, and mechanical life and IP protection level.

As we all known, the majority of manufacturers on the market, especially domestic manufacturers are only passed the DC-21B standard (for general-purpose DC switch non-PV dedicated DC switch test), even worse only had the domestic CCC certification. As the world’s first isolator passed the IEC60947-3(ed.3.2):2015 new standard test, PROJOY PEDS40 / 55 series strictly implement the requirements of PV-1 the new standard. For example, in the DC-21B standard, the product temperature requirements is -5 ℃ ~ +40 ℃, but PV-1 proposed outdoor used temperature is -25 ℃ ~ +40 ℃. At the same time, through laboratory validation, Projoy PEDS 40/55A series isolator can achieve full work in -25 ℃ ~ +70 ℃. At the same time, the old /new standard of the rated pulse voltage requirements, the difference is also very obvious. Old versions of the voltage are not explicitly required, so generally using 1000V voltage, Uimp4VK test, but PROJOY using 1500V rated voltage, Uimp8kV test as new standard requirements, which has requirements of the insulation. We all know that the string inverter requirements IP65 protect level, but the DC-21B is not required as new standard. So only PROJOY PEDS new standard are certificated IP66 protection level, whether it is external switch, or built-in switch installed.

PROJOY DC isolator passed the IEC new standard test, that is also for the industry to establish a higher standard!

Passed the inverter manufactory higher requirements test

We all know that the test sample under the high temperature and humidity conditions can increase the adsorption of water vapor, absorption and diffusion. Many materials expand and deteriorate after moisture, and cause a decrease in material strength and a decrease in major mechanical properties. Adsorption of water vapor insulation material will not only cause electrical performance degradation, in low temperature conditions, but also lead to a variety of different failures.

The “Double 85 experiment” usually means the test under 85 ℃ temperatures and 85 ℃ humidity. According to PROJOY technical staff, in Shenzhen, during an inverter manufactory sample test, the engineer put PROJOY isolator in the 85 ℃ temperature, 85 ℃ humidity test box, manually twist the knob every 2 hours. After 48 hours double 85 test, PEDS40 / 55A isolating isolator plastic parts did not appear deformation, knob mechanism performance was still good, smoothly passed the double 85 test, reflecting excellent structural design of the product. At the same time, Zhejiang inverter company’s short-circuit test is also effective to verify the Insulation performance of the Projoy DC isolator, it is learned that PROJOY is the only manufactory passed the enterprise insulation test.

According to PROJOY stuff revealed that Projoy has passed the entire sample test of the domestic mainstream inverter manufacturers, and entered the supplier sheet including China largest and German largest.

V-0 grade flame retardant material can effectively fire protection

Recent years, photovoltaic power station accidents are frequently. According to incomplete statistical analysis, the electrical fire caused by fire accidents occupies a large proportion. According to industry engineers, many reasons can cause the photovoltaic power plant on fire, not only photovoltaic modules and inverters, but also inverter DC terminals, DC switches, AC connectors and other components are all likely to cause accidents

In the design and development of the switch, the effective use of flame retardant materials can delay the spread of flame. Therefore, according to the plastic flame retardant properties, flame retardant grade is divided into: HB, V-2, V-1 to V-0 step by step increase internationally.

In order to meet the requirements of the new IEC standard, in the 40A / 55A DC isolator development, Projoy isolator shell using the Italian imports V-0 grade flame retardant materials, 0.75mm flame retardant thickness, can be full load work during -25 ℃ to +70 ℃.

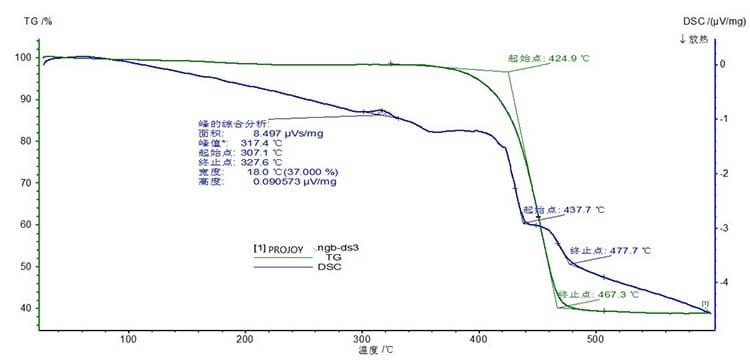

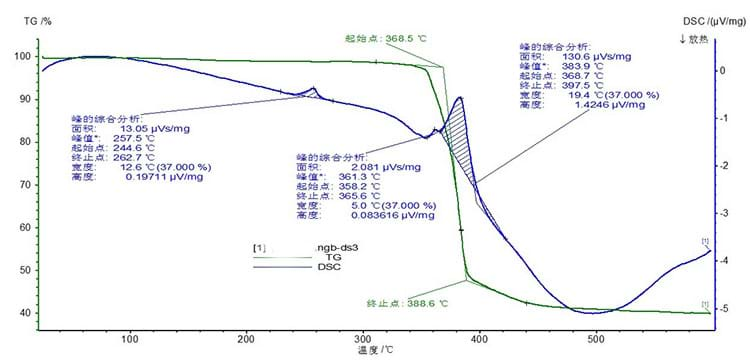

In the synchronous thermal analyzer laboratory test, the plastic shell of domestic first-line supplier PROJOY has obvious advantages than similar domestic products.

PROJOY – Plastic shell temperature test results

Domestic similar products - shell plastic temperature test results

Per the experimental data, the homemade products in 244.6 degrees begin to deform. Due to Projoy isolator using V-0-class imported flame-retardant materials, the isolator will not produce any changes at 300 degree; can effectively prevent the fire hazard!

Deep into the photovoltaic industry, from the beginning of the establishment, Projoy always focused on product development and marketing, to become the pioneer of technology, always adhere to the “Switch to safety!” corporate philosophy, committed to become the inverter and photovoltaic power plant global leader supplier!