Same "DC isolator" and big difference

Date: 2016-10-24In recent years, due to improper selection of DC isolators, resulting in overheating, leakage and sparks, and even fire, continue to occur in the PV power station. And when some inverters, electric box manufacturers do accessories selection, in pursuit of low-cost, the quality of the DC switch is not strictly controlled, resulting in electric shock and fire risk further increased.

Small differences in parameters or have a big impact

Usually, in the choice of DC isolators, the inverter manufacturers will first estimate through the key parameters with adequate margin, and then select the detailed product & specifications base on the site environment.

For example, the “current shutdown capability” is an important parameter for selecting a DC switch. The reason is that, in the photovoltaic system, the voltage and current are high, once the ground fault, high short-circuit current will pull the contacts together, resulting in high short-circuit current, the maximum up to 1000 amperes. If the isolator failed to disconnect the short-circuit current, will cause damage to the photovoltaic system or even fire.

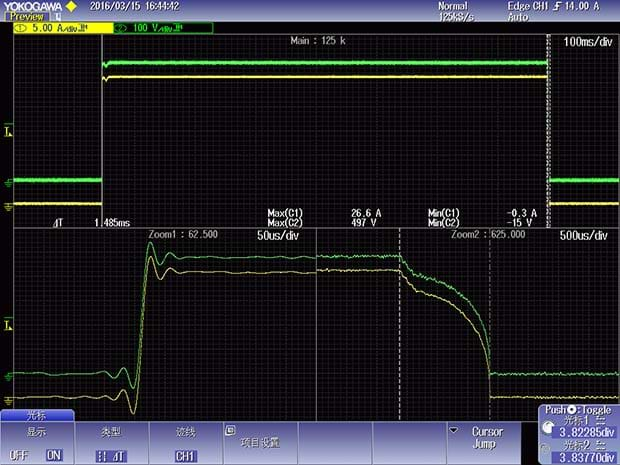

In a recent test of GROWATT, PROJOY brand DC ISOLATOR opening time is only 0.128ms and off-time only 1.458ms, which even much faster than the International famous brands claimed 5.000ms ARC time. Integrated other outstanding test data of PROJOY isolators, GROWATT decide to use only PROJOY isolators in all of their inverters worldwide.

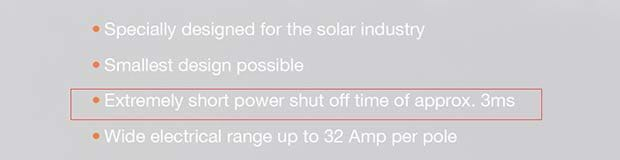

<An European X-Series brand claims 3ms shutdown capability>

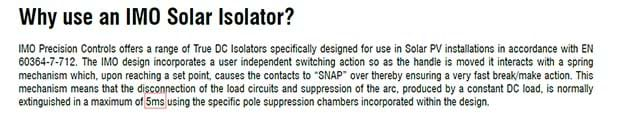

<An European brand S-series claimed 5ms shutdown capability>

<PROJOY DC isolators – off-time 1.458ms>

The raw materials also cannot be ignored

In the selection of DC isolators, in addition to the comparison of product parameters and the necessary sample test, users will also evaluate the qualification of the supplier and the raw materials of the components.

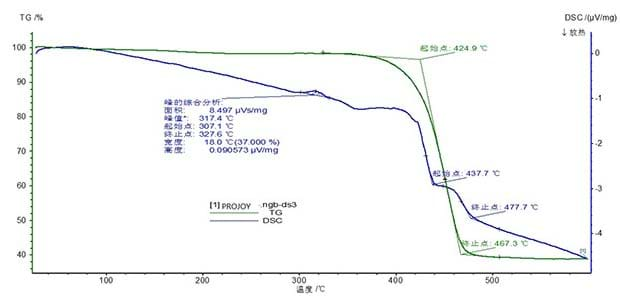

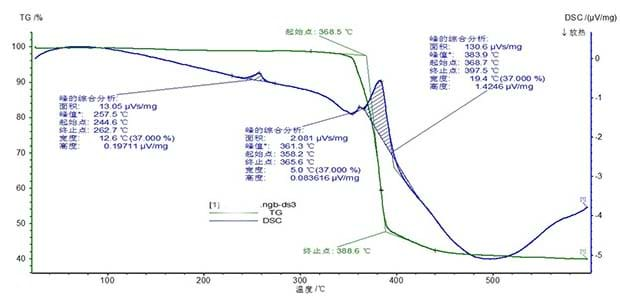

Recently, in a laboratory synchronous thermal analyzer test found that PROJOY and a B company has obvious difference in the outer plastic shell of the same type enclosure DC isolator.

<PROJOY DC isolators – Plastic temperature test results>

<B company DC isolators – Plastic temperature test results>

Through the experimental data is not difficult to find, B Company’s DC isolator enclosure box began to deform in 244.6 degrees, and the PROJOY enclosure box does not happen any change even in 300 degrees.

DC isolators are important in a solar system, so inverter manufacturers, installers and final users should pay attention to detail in the selection. First, initial estimate the isolators through the key parameters and ensure adequate margin. Second, choose the suitable isolator and specifications according to the site environment. Third, verify whether the product parameters can meet the actual needs through experiments. At the same time, it is better to carefully examine the DC isolator manufacturers, for example: quality management, ISO standards, laboratory equipment and the scale of the production line. In addition to the necessary sample simulation testing, suppliers of raw materials should also be evaluation.