Selection and Application of Photovoltaic DC Isolatior

Date: 2021-05-12Working principle

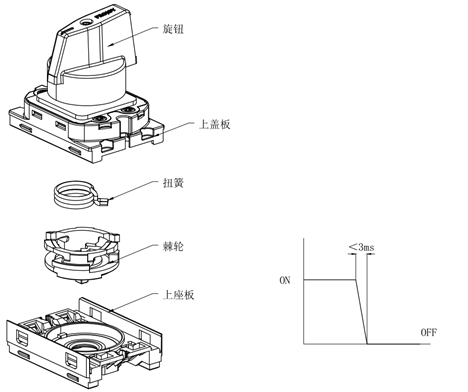

When the photovoltaic DC isolator is in operation, the moving and static contacts should meet the required insulation distance. The contacts should be able to carry the current under normal circuit conditions and the current under abnormal conditions within the specified time, and have obvious disconnection with Logo (ON/OFF). In the initial state, the ratchet and the upper cover buckle are engaged with each other (ratchet is fixed).

During the rotation of the knob, force is applied to the torsion spring, and at the same time, the torsion spring also exerts force on the ratchet. To wait for the knob to rotate to approximately70°, the elastic force of the torsion spring reaches the peak value, it drives the upper cover plate and the ratchet wheel to separate, and the switch is opened. Photovoltaic systems are usually 600~1500V high voltage direct current, Arc is inevitably generated during live opening and closing operations. If the layout of the static contacts is unreasonable, the quality of the arc extinguishing material is poor, or the arc extinguishing speed is slow, it is easy to cause the switch to burn out, and there is a serious safety hazard.

<Basic structure and opening process of DC switch>

Product Model

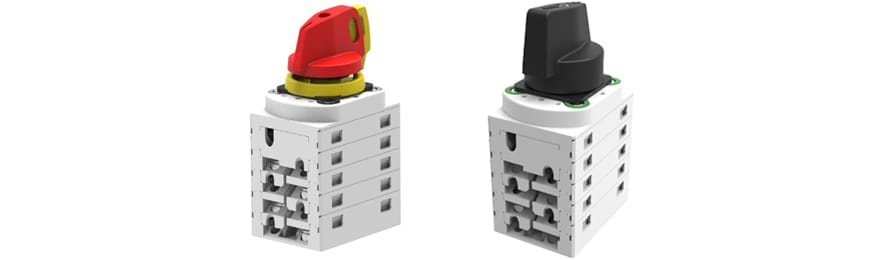

The isolating switch used now is layered layer by layer to achieve the purpose of multi-channel protection (Projoy products can reach 10 layers at present). Because of the particularity of photovoltaic power generation, both the positive and negative electrodes need to be protected, so the two layers of the isolating switch form a loop.

As a photovoltaic system component, Projoy's DC isolating switch is currently installed and used by 80% of inverter manufacturers due to its professional and complete product series. According to different usage scenarios of the product, the requirements of customers are different, and the corresponding product features are also different. The specific classifications are as follows:

(1) Contact installation direction: reverse contact, positive contact, horizontal contact

These 3 contact directions themselves have no advantages and disadvantages, and it will not affect the performance of the isolation switch itself. This classification design is mainly based on actual site installation considerations, that is, whether the photovoltaic lines drawn from it interfere with the circuit board and the ease of operation of the installer to classify and select the contact direction. Because of the subtle difference in structural design, the size of the isolating switch with the same number of layers will have 3~5mm difference.

(2) Depending on whether it is to be fixed on the bracket or not, the earrings are optional:

The function of ears is mainly fixation. If you don't need special fixation, you don't need to consider this feature. For Projoy's current products, the positive contact and reverse contact isolation switches have ears, while the reverse contact DC switch does not have this ear.

(3) According to on-site installation requirements, optional locks are available:

Because in Australia and North America, when repairing photovoltaic systems, engineers often consider non-professional mis-operations. When the isolating switch is OFF, a safety lock is placed on the lock of the knob to ensure the safety of maintenance personnel. Projoy's DC isolation switch products can be padlocked for a variety of installation methods HM, PM, DB, DC, and EL.

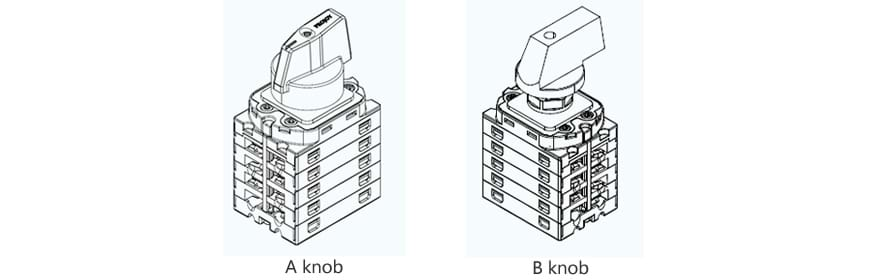

(4) According to the size of the knob, there are two types of knobs: A/B:

The reason why there are two knobs with different sizes is mainly from the user's point of view. The B knob has a long length, which is convenient for customers to rotate, but the disadvantage is that under the condition of limited space, it will interfere with the nearby DC terminal and cannot be rotated; the A knob is small in size and flexible in operation, but the operating force is relatively large.

(5) According to different installation positions, it is divided into built-in isolation switch (protection grade IP20) and external isolation switch (protection grade IP66)

Install an isolating switch in the photovoltaic system. At present, in addition to Australia's mandatory requirement for an external isolating switch, other regions choose to integrate it into the inverter. Recently, with the rapid development of the Brazilian photovoltaic market, the demand for power distribution module installation (DB) series is particularly strong. Projoy’s PEDSC120R-DB32 product has a monthly shipment of 5W.

In addition, when selecting models, there are some details, such as the direction of the knob switch, the type of jumper, the color of the knob, and the requirements of accessories, etc., which need to be selected separately according to different requirements.

Safety requirements

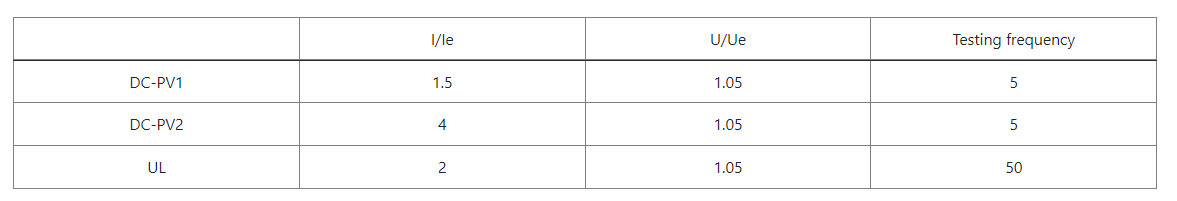

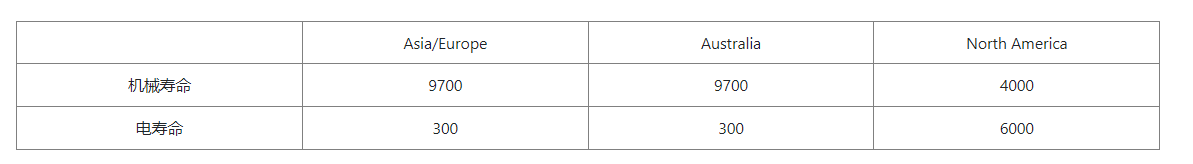

In the certification test standards, no matter which region will place special emphasis on the electrical life and making and breaking capacity of photovoltaic disconnectors, the difference is only in Asia and Europe (DC-PV1), Australia (DC-PV2), and North America (UL). The requirements are different. Table 1 lists the different requirements for switching on and off, and Table 2 lists the different requirements for electrical life and mechanical life:

Table 1 Make and break test requirements

Table 2 Electrical life and mechanical life test requirements

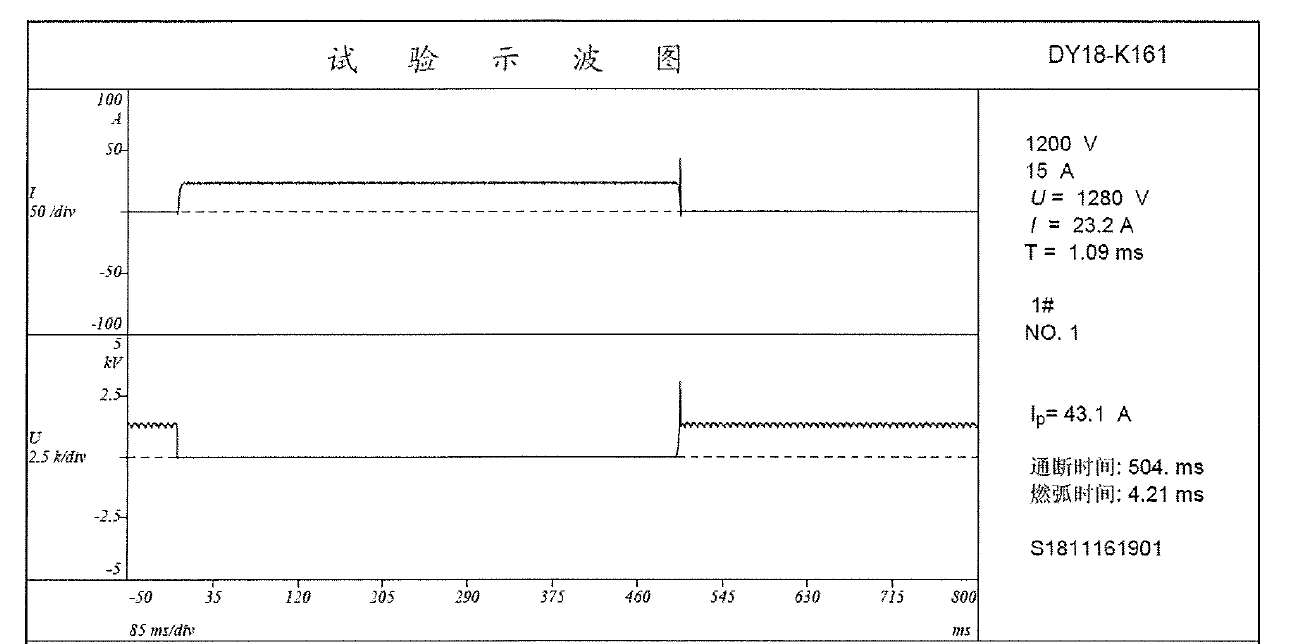

Turn on and break test waveform

As can be seen from the list of parameters, UL Standards have more stringent requirements for products and are closer to the limit test!

To meet these requirements, the choice of raw materials is very important. Projoy's current contacts are NGK beryllium copper imported from Japan. Its high heat dissipation and high conductivity can meet the requirements of use; in addition, the structural design is also critical, the moving reed Double sockets, with two static reeds inserted or separated at the same time. There are two break points in the circuit to ensure the reliability of contact and enhance the reliability of the disconnection circuit. The built-in spring energy storage mechanism shortens the switching time and greatly reduces the length of time of arcing effectively guarantees the physical properties and contact performance of the contact pair. At present, Projoy's DC isolating switch products have obtained TUV, CE, CB, SAA, UL authoritative certifications, escorting the safety of photovoltaic systems.

In addition, the choice of shell material needs to meet the fire resistance requirements of V0-94, and the contacts need to meet at least 48 hours of salt spray test; the whole machine does not drop load at 70℃ or the altitude of 2000m, and in order to adapt to the requirements of harsh environments, it needs to be carried out heat and humidity resistance cycle test.