Understanding AC Connector Ratings: A Comprehensive Guide to Electrical Connectors

Understanding AC Connector Ratings: A Comprehensive Guide

Table of Contents

- 1. Introduction to AC Connectors

- 2. Importance of AC Connector Ratings

- 3. Key Terminologies in AC Connector Ratings

- 4. Voltage Ratings Explained

- 5. Current Ratings and Their Significance

- 6. Environmental Considerations and Ratings

- 7. Safety Standards for AC Connectors

- 8. Choosing the Right AC Connector for Your Needs

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

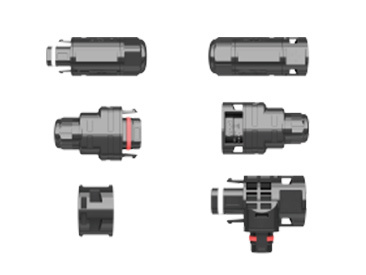

1. Introduction to AC Connectors

In the realm of electrical engineering, **AC connectors** play a pivotal role in ensuring the safe and efficient transfer of electrical power. These connectors facilitate connections between various electrical devices and systems, enabling them to function effectively. Understanding the ratings associated with AC connectors is crucial for engineers, technicians, and even DIY enthusiasts who aim to make informed decisions regarding electrical setups.

2. Importance of AC Connector Ratings

AC connector ratings are not just numbers; they represent the maximum limits that a connector can safely handle. Ignoring these ratings can lead to overheating, equipment failure, or even hazardous situations such as electrical fires. Thus, knowing the ratings allows users to select connectors that match the requirements of their specific applications, ensuring both operational efficiency and safety.

3. Key Terminologies in AC Connector Ratings

Before diving deeper into the specifics of connector ratings, it's essential to familiarize ourselves with some key terminologies:

3.1 Amperage

Amperage, or current, refers to the flow of electric charge through the connector. It's measured in **amperes (A)**.

3.2 Voltage

Voltage is the electrical potential difference between two points in a circuit and is measured in **volts (V)**.

3.3 Wattage

Wattage is the product of voltage and amperage, indicating the power the connector can handle. It's measured in **watts (W)**.

3.4 Insulation Resistance

This refers to the resistance provided by the connector’s materials to prevent electrical leakage.

4. Voltage Ratings Explained

Voltage ratings are critical because they define the maximum voltage that a connector can handle without breaking down. The most common voltage ratings for AC connectors include:

4.1 Low Voltage Connectors

Typically rated up to **250V**, low-voltage connectors are often used in residential applications, such as in lighting fixtures.

4.2 Medium Voltage Connectors

Rated between **251V and 1000V**, these connectors are commonly found in commercial and industrial settings where higher voltages are required.

4.3 High Voltage Connectors

Connectors that can handle voltages above **1000V** are considered high voltage and are usually used in specialized applications, such as power transmission.

Understanding these ratings ensures that connectors are used in appropriate settings, reducing the risk of electrical failures.

5. Current Ratings and Their Significance

Current ratings determine how much electric current a connector can carry without overheating or failing. Choosing a connector with an appropriate current rating is vital for safety and performance.

5.1 Derating Factors

When selecting a connector, consider derating factors, which account for various conditions such as temperature, ambient environment, and installation method. For example, if a connector is rated for **10A** under ideal conditions, it may need to be derated to **7A** in higher temperatures or confined spaces.

5.2 Connector Types and Their Current Ratings

Different connector types have varying current ratings. For instance, **NEMA connectors** are widely used in North America and come in various configurations suited for different current requirements.

6. Environmental Considerations and Ratings

The environment where an AC connector operates significantly influences its performance and longevity. Environmental ratings consider factors such as:

6.1 Temperature Range

Connectors must withstand the temperature extremes of their operating environment. High temperatures can lead to insulation breakdown, while low temperatures can make materials brittle.

6.2 Moisture and Dust Resistance

Connectors are often rated for their ability to resist moisture and dust ingress (e.g., IP ratings). A higher IP rating indicates better protection against environmental contaminants.

7. Safety Standards for AC Connectors

Safety standards ensure that AC connectors meet specific performance and safety criteria, protecting users and equipment. Some key standards include:

7.1 UL Certification

Underwriters Laboratories (UL) certification indicates that a connector has been tested for safety and performance.

7.2 IEC Standards

The International Electrotechnical Commission (IEC) sets global safety standards that connectors must meet, ensuring compatibility and safety across different regions.

7.3 Compliance with Local Regulations

It’s essential to be aware of local regulations that may impose additional requirements on electrical connectors, ensuring compliance for safety and legal reasons.

8. Choosing the Right AC Connector for Your Needs

Selecting the appropriate AC connector involves considering multiple factors:

8.1 Application Requirements

Evaluate the specific requirements of your application, including voltage and current needs, as well as environmental factors.

8.2 Manufacturer Reputation

Opt for connectors from reputable manufacturers known for quality and reliability to ensure performance.

8.3 Cost versus Quality

While it can be tempting to choose a lower-cost connector, prioritizing quality and safety is crucial to avoid costly failures down the line.

8.4 Future-Proofing

Consider potential future needs when choosing connectors; selecting a connector rated for higher amperage or voltage can save you from needing to replace it later.

9. Conclusion

Understanding AC connector ratings is essential for ensuring safe and reliable electrical connections. By familiarizing ourselves with voltage, current ratings, environmental considerations, and safety standards, we can make informed decisions that enhance performance and safety in our electrical applications. This knowledge not only aids in the selection of the right connectors but also contributes to the longevity and efficiency of electrical systems.

10. Frequently Asked Questions (FAQs)

10.1 What is the difference between voltage and current ratings?

Voltage ratings indicate the maximum voltage a connector can handle, while current ratings refer to the amount of electric current the connector can carry without overheating.

10.2 How do I determine the right connector for my application?

Assess the voltage and current requirements of your application, consider environmental factors, and choose a connector with appropriate safety ratings.

10.3 Are all AC connectors the same?

No, AC connectors vary in design, voltage, current ratings, and environmental resistance, making it essential to choose the right type for your specific needs.

10.4 What does IP rating mean for connectors?

IP (Ingress Protection) ratings indicate how well a connector is protected from dust and moisture. A higher IP rating means better resistance to environmental contaminants.

10.5 Why is it important to follow safety standards when selecting connectors?

Following safety standards ensures that connectors meet performance criteria, protecting users, equipment, and ensuring compliance with legal regulations.

With this comprehensive guide, we aim to empower you with the knowledge needed to make informed decisions regarding AC connectors, thereby enhancing the safety and efficiency of your electrical systems.

More News