Top Features to Look for in a High-Quality DC Circuit Breaker

Top Features to Look for in a High-Quality DC Circuit Breaker

Table of Contents

- 1. Introduction to DC Circuit Breakers

- 2. The Importance of Choosing a Quality Circuit Breaker

- 3. Key Features to Consider

- 3.1 Current Rating

- 3.2 Voltage Rating

- 3.3 Tripping Mechanism

- 3.4 Response Time

- 3.5 Temperature Performance

- 3.6 Size and Design

- 3.7 Durability and Longevity

- 3.8 Certifications and Compliance

- 4. Recommended Brands for High-Quality DC Circuit Breakers

- 5. Proper Installation and Maintenance Tips

- 6. Troubleshooting Common Issues

- 7. Conclusion

- 8. FAQs

1. Introduction to DC Circuit Breakers

A **DC circuit breaker** serves a crucial role in protecting electrical circuits from damage due to overloads or short circuits. These devices operate by interrupting the flow of direct current and are essential in various applications, from renewable energy systems like solar power to electric vehicles. Understanding the features that define a high-quality DC circuit breaker is vital for ensuring safety and efficiency in any electrical installation.

2. The Importance of Choosing a Quality Circuit Breaker

Selecting a **high-quality DC circuit breaker** is not merely a matter of preference; it's essential for the protection of your entire electrical system. A reliable circuit breaker can prevent potential hazards such as fires, equipment damage, and system failures. By understanding the features that distinguish quality breakers, we can make better decisions that enhance safety and performance.

3. Key Features to Consider

When evaluating DC circuit breakers, it is crucial to assess several key features to ensure you select a device that meets your operational requirements.

3.1 Current Rating

The **current rating** of a DC circuit breaker indicates the maximum continuous current it can handle without tripping. Choosing the correct current rating is vital to ensure that the breaker will not trip during normal operations yet will still provide protection in case of overloads. This rating is typically expressed in amperes (A) and should align with the specifications of your electrical system.

3.2 Voltage Rating

The **voltage rating** signifies the maximum voltage the circuit breaker can withstand. Using a breaker with a voltage rating higher than the system voltage is crucial to prevent breakdown and ensure safe operation. Always check the compatibility of the voltage rating with your system requirements to avoid malfunction or failure.

3.3 Tripping Mechanism

The **tripping mechanism** of a DC circuit breaker determines how quickly and effectively it can interrupt the current flow. There are various types of tripping mechanisms, including thermal, magnetic, and electronic. Each type has its advantages and disadvantages, so consider the application and operational environment when selecting a breaker with the appropriate mechanism.

3.4 Response Time

**Response time** refers to how quickly a circuit breaker can react to an overload or fault condition. A shorter response time ensures that the circuit is de-energized rapidly, minimizing damage to connected devices. For sensitive electronic equipment, look for circuit breakers with fast response times to ensure optimal protection.

3.5 Temperature Performance

Understanding the **temperature performance** of a DC circuit breaker is essential, especially in environments with fluctuating temperatures. A reliable circuit breaker should maintain its performance across a wide temperature range. Check the manufacturer’s specifications for temperature ratings to ensure reliability in your specific application.

3.6 Size and Design

The **size and design** of a circuit breaker can significantly impact its integration into your electrical system. Compact models may be preferable for applications with limited space, while larger models might offer enhanced features or capacities. Additionally, consider the mounting style and accessibility for maintenance when selecting a breaker.

3.7 Durability and Longevity

A high-quality DC circuit breaker should be built to withstand environmental stresses, including humidity, dust, and temperature variations. Look for breakers constructed from durable materials that ensure longevity and reliability over time. Investing in a robust circuit breaker can save costs on replacements and repairs in the long run.

3.8 Certifications and Compliance

Ensuring that a DC circuit breaker meets recognized industry **certifications** and compliance standards is essential for safety and performance. Look for breakers that comply with standards such as UL, IEC, and ANSI to guarantee quality and reliability. These certifications provide assurance that the product has been tested and meets strict performance criteria.

4. Recommended Brands for High-Quality DC Circuit Breakers

Choosing a reputable brand can make a significant difference in the quality and performance of a DC circuit breaker. Some of the top brands known for their high-quality products include:

- **Schneider Electric**: Renowned for advanced protection solutions, Schneider Electric offers a range of reliable DC circuit breakers suitable for various applications.

- **Eaton**: Known for its innovative products, Eaton provides circuit breakers that are durable and designed for high-performance applications.

- **Siemens**: Siemens offers a variety of DC circuit breakers that are well-regarded for their safety features and reliability.

- **ABB**: ABB is a leader in electrical equipment, known for producing high-quality circuit breakers that meet industry standards.

- **Mersen**: Mersen specializes in overcurrent protection solutions and offers a selection of DC circuit breakers that deliver exceptional performance.

5. Proper Installation and Maintenance Tips

To maximize the performance of your DC circuit breaker, proper installation and maintenance are crucial. Follow these guidelines:

- **Installation**: Ensure that the breaker is installed according to the manufacturer's instructions. Pay attention to the wiring and connections to avoid short circuits and operational failures.

- **Regular Inspections**: Conduct regular inspections to check for signs of wear or damage. Look for any discoloration, corrosion, or loose connections.

- **Testing**: Periodically test the circuit breaker to ensure that it functions correctly. This can involve simulating fault conditions to verify tripping efficiency.

- **Cleanliness**: Keep the area around the circuit breaker clean and free from dust and debris to prevent overheating and ensure optimal performance.

6. Troubleshooting Common Issues

Understanding how to troubleshoot common issues with DC circuit breakers can save time and prevent costly downtime. Here are some typical problems and solutions:

- **Breaker Trips Frequently**: If a circuit breaker trips often, it may be overloaded. Check the current load and ensure it does not exceed the rated capacity.

- **Failure to Trip**: A breaker that fails to trip during an overload can indicate a malfunction. Inspect the breaker for damage or consult a professional for further evaluation.

- **Physical Damage**: If you notice physical damage to the circuit breaker, replace it immediately to prevent potential hazards.

7. Conclusion

Selecting a high-quality DC circuit breaker is essential for the safety and reliability of electrical systems. By understanding the key features, including current and voltage ratings, tripping mechanisms, and durability, we can make informed choices that elevate performance and protect our investments. Remember to consider reputable brands, follow proper installation practices, and maintain regular inspections to ensure long-lasting functionality. Investing time in selecting the right circuit breaker can lead to safer and more efficient electrical systems.

8. FAQs

1. What is the difference between AC and DC circuit breakers?

AC circuit breakers are designed for alternating current, while DC circuit breakers are specifically built to handle direct current. The key difference lies in their tripping mechanisms and the way they interrupt the current flow.

2. How do I determine the right current rating for my DC circuit breaker?

To find the appropriate current rating, assess the total load that will be connected to the circuit. Ensure that the breaker’s rating exceeds this load to prevent nuisance trips while still providing adequate protection.

3. Can I use an AC circuit breaker for DC applications?

Using an AC circuit breaker in a DC application is not recommended, as they are not designed to interrupt direct current effectively, which can lead to dangerous situations such as electrical fires.

4. How often should I test my DC circuit breaker?

It is advisable to test your DC circuit breaker at least once a year, or more frequently in critical applications, to ensure it operates correctly and efficiently.

5. What should I do if my circuit breaker keeps tripping?

If your circuit breaker trips frequently, check for overloads in the circuit and inspect the breaker for damage. If the issue persists, consult a professional electrician for further diagnosis and repair.

More News

Aug 05,2025

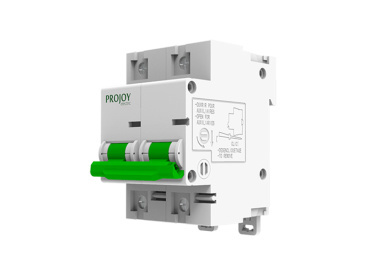

Product Selection Guide: PROJOY PEBS Series Miniature Circuit Breaker

PROJOY Electric has a full range of DC circuit breaker products, including miniature circuit breakers (MCBs) and molded case circuit breakers (MCCBs). According to different application scenarios and requirements, they are divided into high-voltage, low-voltage and waterproof box versions.

View Detail

Mar 13,2025

PV Combiner Box: A Vital Component in Solar Power Systems

Solar energy systems rely on a network of components to efficiently convert sunlight into usable electricity. One critical yet often overlooked device in this chain is the photovoltaic (PV) combiner box. This article explains what a PV combiner box does, how it works, and why it is essential for both safety and performance in solar installations.

View Detail